SMD REFLOW OVEN FOR PROTOTYPING

CONDEN-IT is a complete range of vapour phase reflow ovens dedicated to the

manufacturing of prototype SMT boards.

These ovens are designed for remelting solder paste.

The ovens are ROHS compatibles.

CONDES-IT

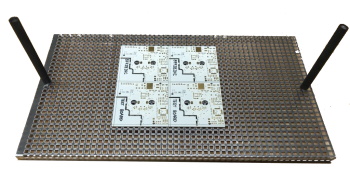

![]() MINI OVEN CONDENSATION

MINI OVEN CONDENSATION

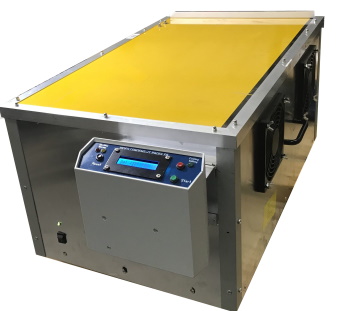

![]() JUMBO OVEN CONDENSATION

JUMBO OVEN CONDENSATION

![]() JUMBO + FUME EXTRACTOR

JUMBO + FUME EXTRACTOR

![]() DINO OVEN CONDENSATION

DINO OVEN CONDENSATION

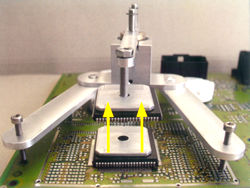

![]() KIT REWORK

KIT REWORK

Vapor phase model

Usable for soldering prototypes and small batches of PCB.

Setting is done via a programming display.

Description

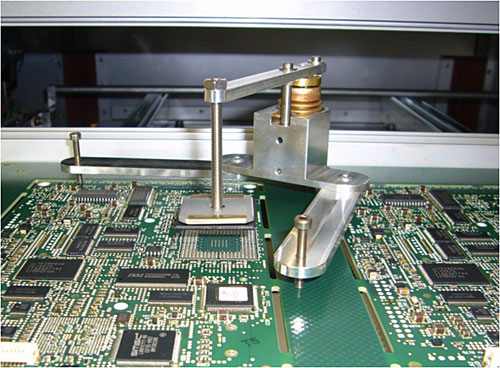

The condensing table ovens are intended for use by laboratories, development

offices and prototype manufacturers and small series of boards.

Components such as QFP, BGA, Flip-Chips and hybrids are treated flawless with

excellent quality results.

Because of their small footprint, condensing ovens can be used anywhere.

| Specifications | Model MINI (model stopped) | Model JUMBO | Model DINO (model stopped) |

| Fluid |

Galden LS230 for applications ROHS

Quantity; 0,5 Liter = 910 Grams |

0,8 Liter | 1,6 Liters |

| Cycle time | 30 - 120 seconds depend on PCB | same | same |

| Heating time | 15 minutes | 25 minutes | 35 minutes |

| Complete cycle | 30 minutes | 45 minutes | 60 minutes |

| Soldering temperature | 210 à 240 ºC (dépend on fluid) | same | same |

| Cooling | air forced | air forced | air forced |

| Fluid quantity | 350 à 500 ml of GALDEN | 800 à 1350 ml of GALDEN | 1600 à 1900 ml of GALDEN |

| Dimension PCB max ( L x W x H) | 240 x 170 x 20 mm | 430 x 230 x 20mm | 580 x 460 x 20mm |

| Dimensions (L x W x H) | 400 x 315 x 305 mm | 605 x 385 x 450mm | 840 x 640 x 460mm |

| Weight | 6 kg | 15kg | 25kg |

| Electrical | 230V 50Hz | 230V 50Hz | 230V 50Hz |

| Power | 1000W / 5amp | 2000W / 10amp | 2500W / 10amp |

Vapor phase is an alternative to air and IR reflow ovens. Vapor phase offers

a better consistency in quality than small reflow ovens.

With vapor phase soldering, the PCB is submerged in hot Galden vapor. This

vapor transfers heat to the PCB and melts the solder.

Because the Galden vapor is always at the same temperature, the process is

very reliable. No components are overheated and no solderjoints are underheated.

Poor the right amount of Galden in the bottom of the container. You only need to do this the first time before use. Switch on the device. Place the ready-to-solder PCB on the grid. Close the lid and wait until the Standby LED is green. You can start the soldering process by pressing the start button. The Galden at the bottom of the container is now heated and the vapor will rise until above the PCB. When the device registers that the vapor has risen above the PCB, it will shut down the heating and it starts cooling the container with fans. The vapor will condense and will flow back into the bottom of the container. You can take out the soldered PCB now. Use protective gloves, because it is still hot. The whole process only takes about 10 minutes. The Galden liquid needs to be purchased separately. You need a minimum of 350ml to use the Mini Condens-IT. Each soldering cycle a few ml of Galden gets used up.