SOLDERWAVE is a selective soldering and desoldering station for TH components.

The use of this station is for electronics production and repair of boards.

It replace the manual operations with a hot iron which are very

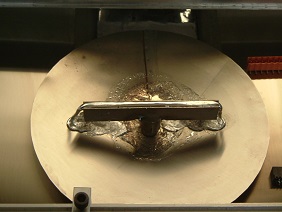

costly. The principle of SOLDERWAVE station is sending the molten alloy on the

surface of the nozzle at a predetermined height with or without overflow. The

presence or the flow

alloy can be used for soldered or desoldered component.

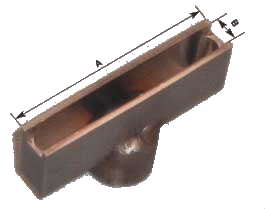

The nozzles are interchangeable

quickly. The PCB is placed on a adjustable frame holder with fingers.

The method of soldering or desoldering is very simple to implement, fast and

repeatable.

We can make tests on your boards if needed.

| Model Solderwave | |

| Maximum alloy temperature | 350°C |

| Maximum PCB size | 300 x 400 mm |

| Solder pot | 8 Kg |

| Size | 578 x 482 x 145 mm |

| Total weight | 23 Kg |

| Power supply | 230V 50Hz |