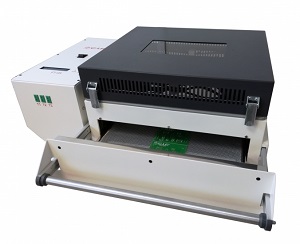

This reflow oven is compatible with Rohs lead-free technologies.

CIF FT05.ADVANCED "Made in France"

![]() Documentation

Documentation

Forced convection reflow oven for prototypes and small series.

The FT05.ADVANCED model is controlled by the SMTix 2.0 software

It can be optionally connected to a filtration station

Complete visualization of the board through a large window

Compact model but offering a useful reflow area of 350 x 400 mm

Possibility to create up to 10 temperature steps

LCD display of the different set points

Unlimited storage of profiles

Heat distribution by forced convection

Very simple programming for an immediate start

Advantages

| Model | FT05.ADV |

| Reference | V900324 |

| Heating | 2 levels |

| Temperature control | micro computer |

| Working temperature | up to 300°C |

| Working area (max PCB size) | 350 x 400 mm |

| Quartz heating elements | 4 x 1 KW |

| Software SMTix-2.0 | Included |

| Thermal stabilisation | about 5 minutes |

| Max heating time (thermal treatment) | 70 hours max |

| Dimensions ext. L x D x H | 730 x 640 x 380 mm |

| Weight: | 39 kg |

| Power supply: | 220V mono / 20 Amp |