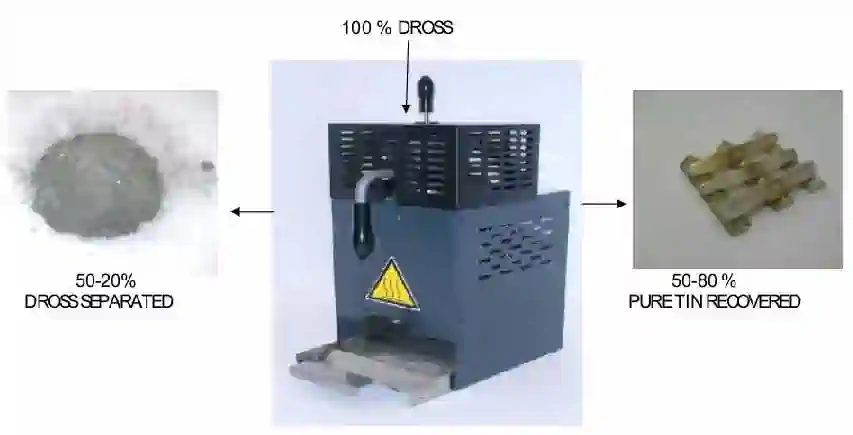

The dross separator DS-400 is designed to recover pure allow from working

impurities

oxides generated from the wave soldering with lead or lead free process.

The

dross resulting

of the solder process requires special handling that is very costly.

This unit

not only provides

a considerable savings cost, but has the added benefit of being right in your

own

manufacturing environment.

DS-400 is primarily used in the electronic industry but has proved by

eliminating the

outsourcing, to be very useful in other parts of the tin processing industry

and the consequent

disposal of alloy waste.

DS-400 activates the specific weight of the materials that have to be

separated. After a

filtering process, the reusable alloy settles in the lower section of the pot

while the dross floats

on the surface. The reusable have identical characteristic to the present alloy

captured in the

solder pot.

Possible amortization after processing 100Kg of lead-free alloy

TECHNICAL FEATURES

:

| SOLDER CAPACITY | 10 Kg |

| POWER SUPPLY | 230V (110V OPTIONAL) 50/60 Hz |

| PROTECTION FUSE | 3 KW |

| POWER CONSUMPTION | 16 AMP |

| EMPTY WEIGHT | 13 Kg |

| SIZE | 260 x 460 x 630 mm (W x D x H) |