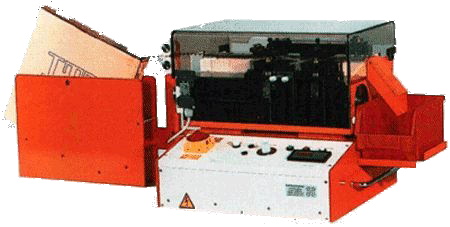

To eliminate belt-tolerances the Streckfuss machine Type C 069 G was developed with an integrated touch-facility.

With this all usual in the trade component-belts which meet the IEC-Norm can effortless be processed.

The component is formed and cut with a maximum tolerance of ±0,1 mm.

The supply of components is exclusively done by reel.

For this the machine has a combined location for reel and amo-pack.

To save set-up time all necessary toolkits for specific formings are mounted in one unit.

These toolkits can be inserted or exchanged within a very short time.

When inserting a toolkit the driving-mechanism automatically will be locked.

The machine is prepared to keep 2 processing-units.

One unit performs upward formings and the other performs downward formings.

After the components have been formed and cut they are ejected into a bin for collection.

| Specification | |

| - dimension | 1100 x 550 x 500 mm |

| - weight | approx. 30 kg |

| - electrical | 230 V / 50 Hz / 200 W |

| - compressed air | 6 bar |

| - model | double-processing unit (forming upwards and downwards is possible) |

| - pitch | 2.54 mm - 5.08 mm - 7.62 mm |

| - lead Ø | 0.8 mm |

| - operation | engine (continuously variable) |

| - components | Sticks or loose |

| - production rate | 3.500 pcs/hr |