![]() Documentation DR-30

Documentation DR-30

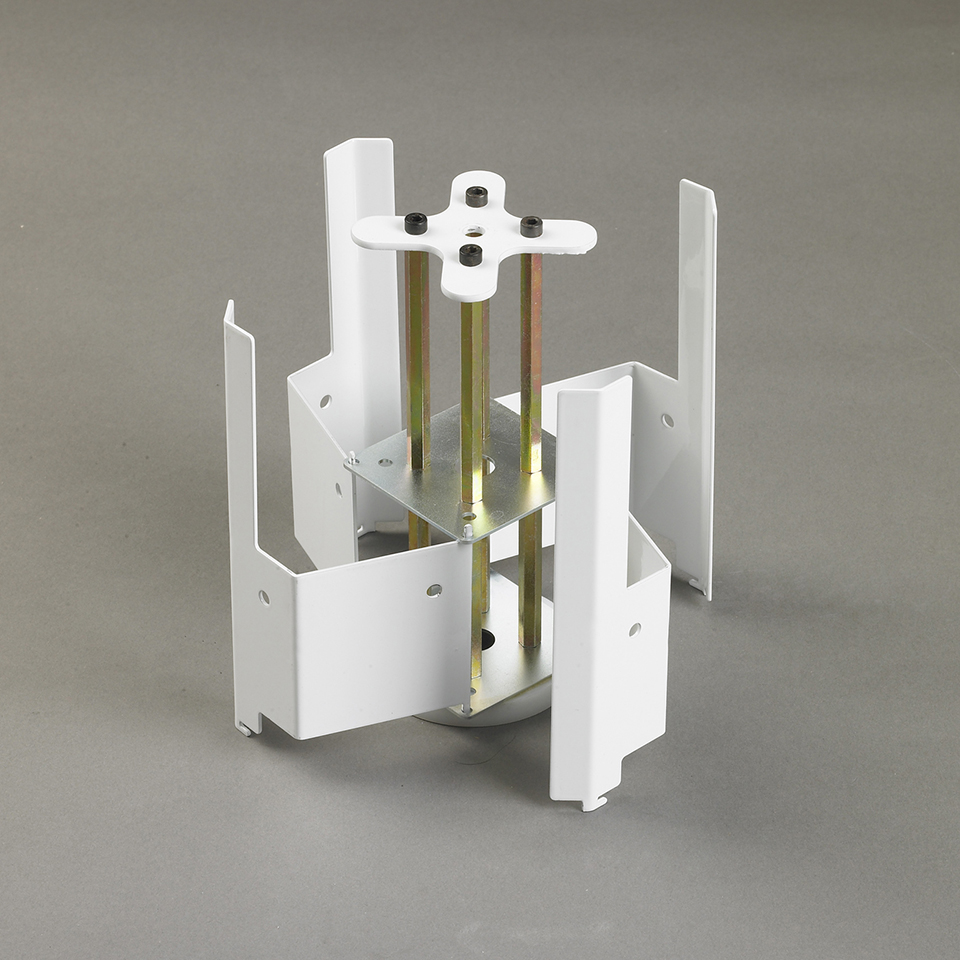

![]() Parts DR-30

Parts DR-30

The DR 30 solves this problem with smooth acceleration and braking of the

rotary plate.

Increases the productivity of cutting machines.

Simplifies unwinding of cable reels and cable reels

Prevents the cable from twisting and knotting

Spring loaded guide pulleys ensure smooth acceleration and braking

Datas

:

The DR-50 HORIZONTAL DE-REELER has been designed as a support tool for the cutting machine. In addition to preventing excessive strain on the machine, it also serves to hold the material in constant tension and ensure a more precise cut.

This is made possible by an adjustable force tension arm, which is connected to the braking device of the reel, thus maintaining the material in constant traction

TECHNICAL SPECIFICATIONS

:

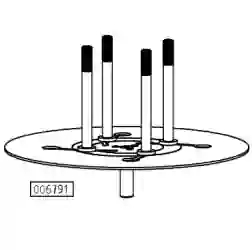

The needs for some types of materials (flat cables, glass fiber cables,

sheaths, etc.) foresee the acquisition of these by unrolling the package (skein

or coil).

This passive bench-top unwinders have the possibility of being quickly adapted

to the different shapes or dimensions of cables, sheaths, seals, etc.

If necessary the central pivot can be quickly rubbed with a knob in order to

change the grip tension or to avoid material losses due to inertia.

UNROAL solves unwrapping problems of wires on coils thanks to an automatic

or manual towing process.

It is extremely seful for those firms producing electric cables and for firms

supplying their customers with big stocks of cables.

UNROAL is equipped with security details that automatically prevent access

to the tool while in action.

A second useful feature of the UNROAL is the absorption of the initial

propulsion of the automatic machinery through a tensionare stock Finally it

comes with an handy counts meter to help the operator in cutting cables in

the length required.

UNROAL is EC certified.

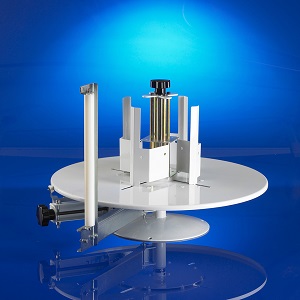

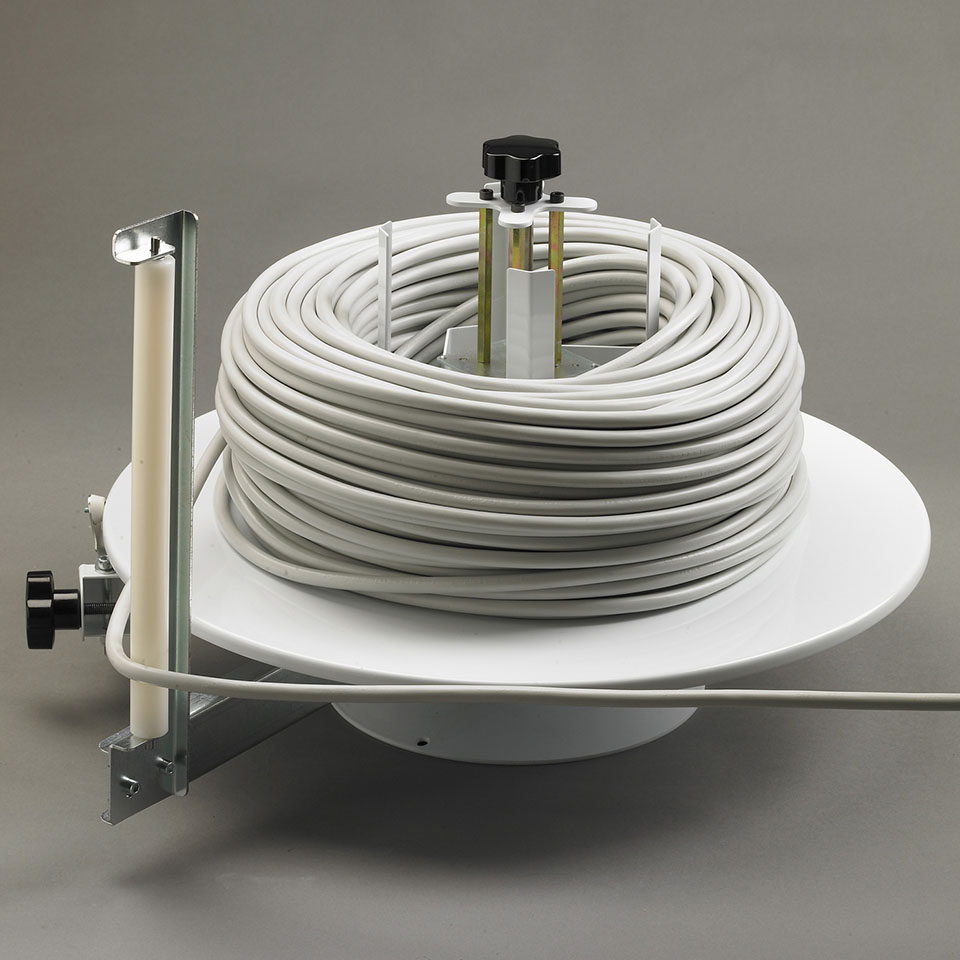

The motorized unwinding system EASY UNROAL can automatically unroll cables

stored in coils and reels up to 400mm in diameter and a maximum of 35kg.

A system of slotted pins allows to unwind skeins of different diameters, while

cables or pipes stored on reels can be uncoiled using only the central shaft.

An adjustable knob allows to change the engine revolutions speed, while a

switch reverses the direction of rotation.

A sensor placed at the base of the two metal columns, with inside them a

sliding pin, allows the START / STOP of the engine once required the use of the

material.